Submerged Pulse Valve DMF-Y-40S

Submerged Pulse Valve DMF-Y-40S

| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Terms of Trade: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 7 Days |

| Packaging: | Inner Boxes,Cartons,Wooden Cases,Pallets etc. |

|---|---|

| Productivity: | 8000pcs per month |

| Brand: | Brando |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | Ningbo,China |

| Supply Ability: | 8000pcs per month |

| Certificate: | ISO.CE |

| Port: | Ningbo,Shanghai,Tianjing |

Basic Info

Model No.: DMF-Y-40S

Click on the follow link to find out more information: https://www.brandopneumatic.com/pulse-jet-valve/

Company Info

- Company Name: NINGBO BRANDO HARDWARE CO.,LTD

- Representative: Lu Jin Jun

- Product/Service: Solenoid Valve , Solenoid Valve Coil , Solenoid Valve Armature , Pulse Jet Valve , Refrigeration Solenoid Valve , Pneumatic Solenoid Valve

- Capital (Million US $): 1000,000RMB

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 81% - 90%

- Total Annual Purchase Volume (Million US $): US$1 Million - US$2.5 Million

- No. of Production Lines: 10

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 3,000-5,000 square meters

- Factory Location: Ningbo

- Contact Person: Mr. Brandon Bao

- Tel: 86-0574-83879820

Premium Related Products

Other Products

Hot Products

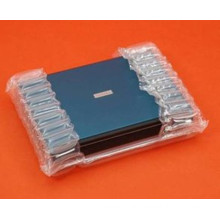

Promotional Inflatable Air Column Bags for Wine BottleInflatable air cushion column bag for toner cartridgeCustomized wholesale brown kraft paper envelope cheap bubble envelopesCoextruded Multi-layer Thermoforming FilmMulti layer Nylon coextruded film for making air columns bags filmHigh barrier multi layer Nylo/EVOH co-extruded plastic shrink film for packing foodPE/PA material air bags cushion wrap roll protective packaging for mailing fragile goodsPE/PA transparent Plastic Air columns Bag bubble packaging for cushion protective packaging toner cartridgeLow cost Inflatable Air Column Bags for cushion protective packaging glass bottle in transportation processHigh quality Inflatable Column Air Bags,Air Cushion Bags for protective packaging milk powder canFactory Wholesale Cheap Shockproof Wine air filling cushion protective Packaging Bag for wine bottleperfect protective packaging buffer mini cushion machineair cushion fill air filling machinehigh level and quality red wine air column wraphot sale Logo customized for e-commerce air bubble film bagChina Shanghai manufacturer air bag